By The Metric Maven

The British documentary series Men of Iron has an interesting overview of engineering in the Victorian era. In the first episode, they discuss the work of Engineer Marc Isambard Brunel (1769-1849). Brunel fled France during the French Revolution and arrived in England. Before Brunel, Engineering mostly involved the application of muscle to a problem. The documentary states: “A radical new engineering approach was needed. The man who would provide it was Marc Brunel.”

They then note:

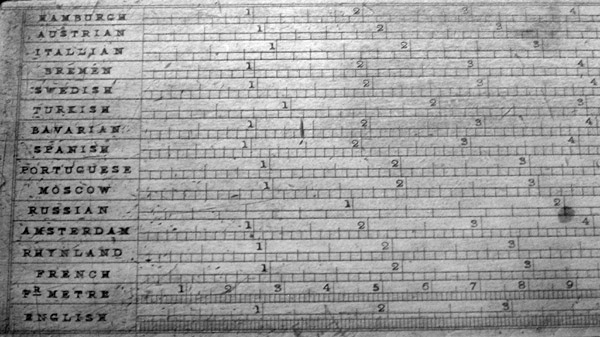

Narrator: Marc brought with him a closely guarded Engineering secret from the French Military, something we now take for granted: technical drawing.

Dr Simon Schaffer: “One crucial element in the Brunel system is paper. A world of paper. This draftsman’s skill was an absolutely crucial element in the Brunel system, because it meant you could cheaply try alternatives, where different elements can be combined and recombined, scales can be changed cheaply, and then successfully translated back into the real world.

Engineering drawing and 3D engineering analysis are so ubiquitous today, it’s hard to imagine a time when they did not exist. Indeed it is the paramount importance of engineering drawings, that is often used as a red herring by anti-metric people, to stall change.

When Americans showed up in Panama, the French had been working on a canal from 1881-1889. The US had purchased the French equipment and excavations for $40 million. The French engineering surveys, equipment and such were considered to be worth about $10,000,000. The work had been done in metric, but in this case it was decided that it made the most sense (to the American Engineers) that it all be changed to imperial measurements. I have uncovered one exception where American Engineers and Technicians had no choice but to use metric. This article from the October 6, 1907 San Francisco Call reports on what happened when there was no choice but to use metric drawings:

The endorsement of metric was a bit back handed, with the article seeming to praise the American workers ability to adapt—to a much simpler system of measurement. Given the time, I’m sure Americans would have attempted to convert all the drawings to inches, despite their lauded adaptability, but a time schedule appears to have forced their hand.

The cost of converting to imperial from metric in America is never a budgetary problem—but converting to metric always is. For example, New Scientist reported on June 22, 2009 that NASA was not going to honor its statement that Orion would be metric. It was claimed that:

The sticking point is that Ares is a shuttle-derived design – it uses solid rocket boosters whose dimensions and technology are based on those currently strapped to either side of the shuttle’s giant liquid fuel tank.

And the shuttle’s 30-year-old specifications, design drawings and software are rooted in pounds and feet rather than newtons and metres.

Let’s see, 30 year old design drawings would place them as having been drawn in about 1979 or so. When I worked in Aerospace, in the early 1980s, drawings were still done on drawing boards. It was not until around 1987 that I encountered the first project which began to use very primitive CAD software. There was considerable inertia against using Computer Aided Design (CAD), and many drawings were still created by hand. What the NASA administrators apparently are arguing is that they would find it more cost effective to use pen and ink drawings of shuttle solid rockets, than use the nice newfangled software like Solidworks or some other 3D CAD software. Was NASA creating a next generation launch vehicle, or slavishly following 30 year old paper Engineering Drawings with imperial dimensions?

The Engineering Drawings Brunel created in the 19th century, were a great advance, but an even larger one is the development of modern CAD systems. With hand drawings there was never a guarantee of how all the parts, boxes, cables and such will fit. It would be too much work to make complete 3D drawings by hand with all the components integrated. There were always unexpected problems during a build where a device did not quite fit where it was supposed to according to the drawing.

Would it not make more sense to design the Constellation vehicle in metric, with CAD, only using the previous hand drawings as guides? Today modern CAD systems utilize “multiphysics” analysis. What this means is that when you draw up a design, one can use now built-in mathematical methods like the Finite Element Method to look at stresses on a structure, see how it changes with heat, analyze the electrical properties for communications and other details which were unthinkable in 1979. In 1987, the first CAD system incorporating my designs had only wire-frame images. What is the cost of bothering with 30 year old shuttle drawings?—rather than using the situation as an opportunity to reform the system and convert to metric.

Newscientist quotes a NASA spokesman:

“The Shuttle and US segments of the ISS were built using the English system of measurements,” says NASA spokesman Grey Hautaluoma.

First, as noted, the Space Shuttle is over three decades old—and now retired. Second, using the International Space Station as an example, is not a particularly good choice for justifying NASA’s decision to continue with its use of barleycorn inches. Notice the quotation states: “US segments of the ISS.” Here is what that means. In March 2001, Michael Milstein would comment about what happened with metric and the ISS in Air & Space magazine:

“Such lack of backbone may be why the U.S. portion of the International Space Station is built in Imperial Units while the rest of the super-expensive structure has been constructed in metric. About 10 years ago NASA gave serious thought to the idea of building the whole thing in metric, but decided that would drive the cost way up. All the NASA contractors were tooled to build parts in inches and pounds; converting to metric would have required revised designs and new machines. So instead they developed an elaborate and costly computer-modeling and cross-checking procedure to make sure that metric and Imperial parts fit together and work properly.”

“Right now the Russians are controlling the space station, figuring propulsion exclusively in metric units. Once the on-board laboratory (expected to have launched January 18) is up and running, the U.S. will take over control exclusively in Imperial units. When I asked spokesman Kyle Herring of NASA’s Johnson Space Center in Texas what would happen if there were some confusion between the two, if a maneuver supposed to be carried out in pounds of thrust were actually done in kilograms or the other way around, he explained that the station’s propulsion system operates at such low thrust that even a major miscalculation couldn’t send it spiraling into the atmosphere.”

This is not exactly a profile in international cooperation by the US. We’ve discussed NASA and Aerospace enough, how about the commercial sector of the United States?

I worked at one of the last companies to make televisions in the US, along with other consumer products. The one thing I noted over and over was that we almost never went back to any of the old engineering drawings. We were always designing new, and different cases, electronics, and so on. Why on earth would one consider going back and converting any of the old drawings from imperial to metric? It was my good fortune that this debate was never to take place at this company. It had already been changed to metric. This occurred because it was purchased by a European company. They were surprised metric had not been mandated and did so. The company was metric when I arrived.

I then joined a small start-up, designing passive wireless devices, it was all inches and imperial again. Later, when the company was purchased, I was given the choice to use metric or imperial, but could not change during the design cycle. When I started using metric again, I realized that I very, very seldom ever looked at old drawings, I was designing new products. The canard about “do you know how much it would cost to go back and convert all our old drawings?” is just an anemic reactionary excuse without basis. There is never a statement “do you know how much it’s going to cost us not to use metric?”

In the Commercial Engineering sector, changing to metric did not involve any feigned angst ridden indecision. One day I just changed everything to metric. In Aerospace and Defense, the hostility toward metric appears to be a symptom of engineering design ossification. When confronted with metric NASA generates statements laced with metric hysterics (again from Newscientist):

NASA recently calculated that converting the relevant drawings, software and documentation to the “International System” of units (SI) would cost a total of $370 million – almost half the cost of a 2009 shuttle launch, which costs a total of $759 million. “We found the cost of converting to SI would exceed what we can afford,” says Hautaluoma.

Nice quotation marks around “International System” NASA—as if 95% of the population of the planet didn’t use metric, and SI is not international. These cost numbers seem to appear out of thin air, without a single metrication effort undertaken, even on new small projects. What I hear is just a lot of howling, the distressed howling of an agency which has become fossilized and is now asked to change. NASA was the agency which placed men on the moon in less than ten years. NASA agreed in 1988 that it would change over to metric. It simply insults one’s intelligence to believe that metric conversion is so difficult, it could not be accomplished by NASA in 24 years–and Engineering Drawings are the problem? It’s clear that legislation compelling US industry, education and government to become metric—without an open ended “transition period” is required. If no due date is given for homework, it’s doubtful that a student will ever bother doing it. If the student is allowed to determine their own “transition period” it will become of infinite length. The US needs a due date, or it will never do it’s homework.. The rest of the world did its homework 30 years ago, while America remains an effete truant.

If you liked this essay and wish to support the work of The Metric Maven, please visit his Patreon Page and contribute. Also purchase his books about the metric system:

The first book is titled: Our Crumbling Invisible Infrastructure. It is a succinct set of essays that explain why the absence of the metric system in the US is detrimental to our personal heath and our economy. These essays are separately available for free on my website, but the book has them all in one place in print. The book may be purchased from Amazon here.

The second book is titled The Dimensions of the Cosmos. It takes the metric prefixes from yotta to Yocto and uses each metric prefix to describe a metric world. The book has a considerable number of color images to compliment the prose. It has been receiving good reviews. I think would be a great reference for US science teachers. It has a considerable number of scientific factoids and anecdotes that I believe would be of considerable educational use. It is available from Amazon here.

The third book is not of direct importance to metric education. It is called Death By A Thousand Cuts, A Secret History of the Metric System in The United States. This monograph explains how we have been unable to legally deal with weights and measures in the United States from George Washington, to our current day. This book is also available on Amazon here.